Powers Manufacturing Internship

I currently am an intern with Powers Manufacturing in Waterloo, Iowa. Powers focuses on manufacturing uniforms including football, baseball, hockey, lacrosse, and wrestling. They create custom uniforms of superior quality, and take pride in their attention to quality.

I am in the quality assurance area at Powers, so I inspect various uniforms. Along with inspecting finished garments, I also check garments going through the sewing line. I was also able to shadow different departments to see what goes on in those areas. I have accomplished a lot learning wise. This internship was not a typical experience, but I will never forget working at Powers. Being a designer, I don’t really think about trying to design something that will be cost effective to sew and produce. Being able to see the manufacturing side of the business was extremely interesting and eye opening. My greatest accomplishment was everything that I learned that I can take with me in my future.

I am in the quality assurance area at Powers, so I inspect various uniforms. Along with inspecting finished garments, I also check garments going through the sewing line. I was also able to shadow different departments to see what goes on in those areas. I have accomplished a lot learning wise. This internship was not a typical experience, but I will never forget working at Powers. Being a designer, I don’t really think about trying to design something that will be cost effective to sew and produce. Being able to see the manufacturing side of the business was extremely interesting and eye opening. My greatest accomplishment was everything that I learned that I can take with me in my future.

I started my internship on January 25th and my first few weeks of my internship went well. My first few days were spent training for quality assurance and getting accustomed to the job. I enjoyed being able to work with clothing every day, and well as looking at the details of uniforms. Pretty early on in my internship I decided with my supervisor to design a football uniform. As a designer, I wanted to incorporate everything I was going to learn into designing.

Under Armour is working on designing a new uniform, and I was able to shadow the process of how a uniform gets started and ends up going through the process. I followed a new football jersey through most of the process so far. When a new design is being created, they work with Under Armour for those uniforms, and it takes a lot of time to go back and forth with one another and figure out exactly how they want something to look. Each side needs to be patient with the other side to get a complete finished product.

First, I was able to talk with a coworker about the technical packs needed. Under Armour had sent a sketch of what they were looking for, and the patternmaking team matched the uniform to the best of their ability to what the sewers could sew. The first prototype (not a complete uniform, only had the top style lines) was created and sewn then sent to Under Armour. Then, UA sent changes needed back to Powers. The patternmakers lay out the patterns and fix and issues. Sometimes this part was difficult because there was a lot of waiting for answers before making decisions. It seemed like this was probably a common issue of Under Armour wanted something specific and the Powers team trying to figure out how to make it work. Then, a second prototype was created as a complete jersey. A sewer was also timed for certain actions, which ultimately end up affecting the overall price of the uniform. This jersey is currently still being talked about and designed, so there is a long process of creating a new design.

I feel like I have accomplished being focused on work and still making time for other designing stuff when I get home. I also have received the knowledge of having to work with a large company, like Under Armour, and seeing the relationship for designing new uniforms. As a designer, sometimes you need people to be able to make a garment more achievable, so I enjoy seeing that process.

My overall goal with my internship was to gain more knowledge about the entire manufacturing process. Every week, I wanted to learn something new and be able to apply that knowledge towards future endeavors. This internship was my opportunity to learn and grow, and my full attention was completing my internship. Having an inside look at what all has to happen to garments before they end up in the hands of the purchaser was a great experience. The sewers work quite hard to get things done and meet deadlines. People do not think about the processes behind garments they are ordering, and I have a close look at those processes. I learned a lot about the industry, and the behind-the-scene processes. It was interesting to see the actual garments being constructed and everything that goes on to create a garment. I enjoyed working so closely with the manufacturing process.

Project

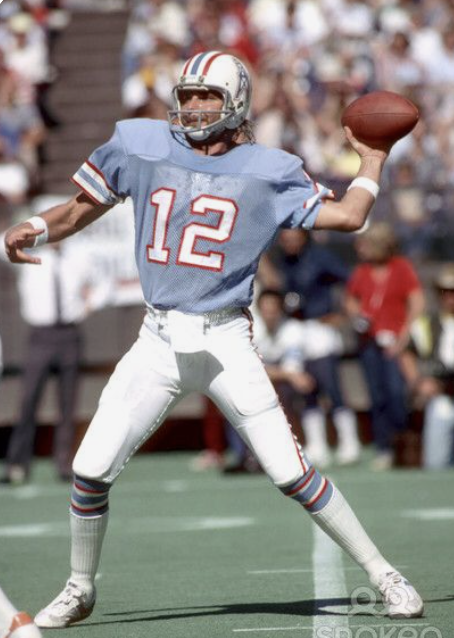

For my project at Powers, I decided to design a new jersey for football. Powers has their own line of uniforms, along with producing uniforms with Under Armour. For my project, I focused on designing a uniform specific to Powers Manufacturing. My inspiration for my design came from retro football uniforms, along with experimenting with different fabric choices and trying to make the uniform more eco-friendly.

Football - Spring 2023

beginning inspiration

- retro inspired football uniform

using stripes, retro lines, longer sleeves

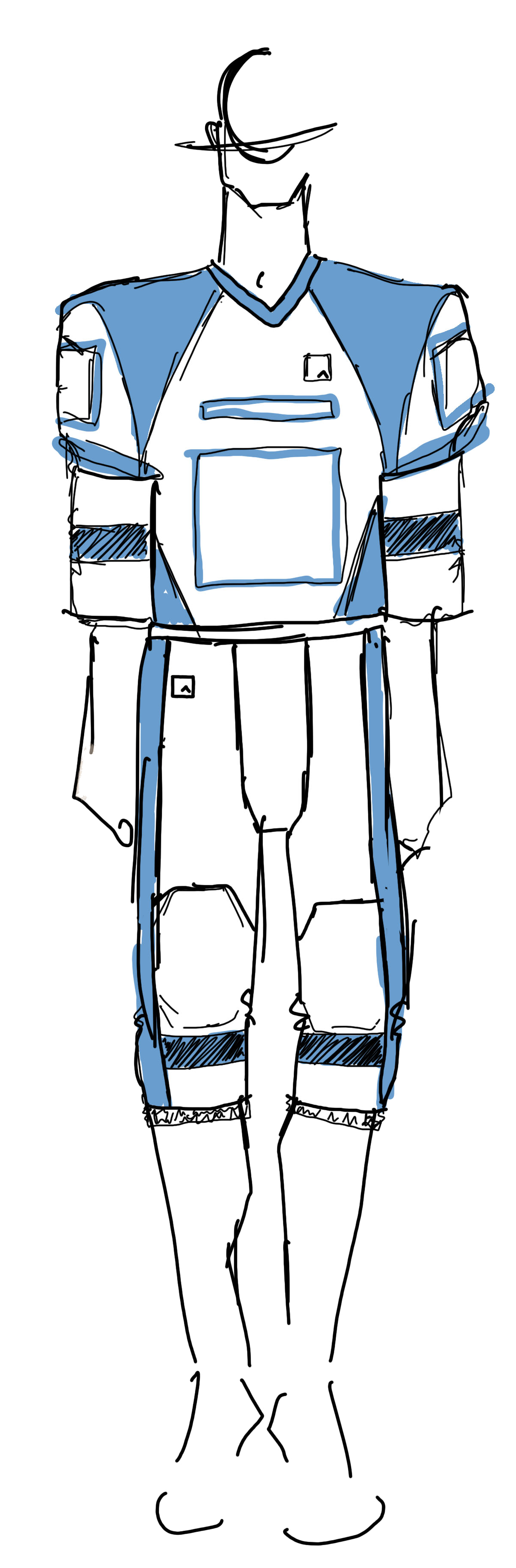

initial sketches

Research:

many athletic uniforms are made of polyesterat Powers, polyester is a common ingredient to the uniforms along with nylon

both polyester and nylon are synthetic fabrics, so man-made textiles that are used at substitutes for natural

fibers

there are many articles and information on the impact of synthetic fibers on the environment: here

ulimately synthetic fibers are aiding to pollution and impacting the environment in a negative way

benefits of polyester in uniforms: durable, wrinkle-resistant, moisture wicking

cotton, hemp, silk, and linens are all common ethical and sustainable alternatives to polyester,

but would they be good for athletic uniforms?

but would they be good for athletic uniforms?

many athletic brands are already making the switch and are caring for the environment by using more ethical alternatives

see the brands here

using recycled polyster fabric would be a great alternative to using polyester in athletic uniforms. minimizing the impact of clothing in any way will ultimately be beneficial and help the environment

process sketches

-

coloring options, symbol placement, line placements

Power UP - black base uniform

sketch

illustration

Power UP - white base uniform

sketch

illustration

POWER UP JERSEY / PANT

Power UP jersey features elbow length sleeves with elastic around cuff, belt length body with technical woven fabric on the front and back top body. Stretch knit sleeves, side inserts, upper sleeve inserts, two ply yoke, sublimated yoke inserts. Stretch knit 1” mitered V-neck and cuffs. Side insert body is vented mesh.

Specify color preferences for:

• Body • Neck • Cuffs • Sleeves • Side Insert • Upper Sleeve • Sleeves • Sleeve Inserts

Sublimated sleeve logo patch add $20.00

NOTE: This jersey is designed for any of our standard 1 or 2 color number fonts in 8” front and 10” back numbers.

Power UP pant features mock negative fabric body with sublimated side and knee insert. Flyless front, tie waistband with two interior concealed slots. Two ply crotch, three piece back with self material thigh and knee pad pockets set with zigzag stitch.

Specify color preferences for:

• Body • Knee and Side insert

POWER UP JERSEY PM033JM - $150.00

1 or 2 Color (Team Name / Stretch Twill Numbers 3”, 8” & 10”)

POWER UP PANT PM024PM - $98.00

With One Sublimated Patch Logo - $108.00